Horizontal drilling in the Wadden Sea National Park

05.10.2023

05.10.2023

1 Introduction

Grid expansion in Germany is picking up speed. The shift to renewable energy sources plays an essential role in this. The federal government’s declared goal is to achieve climate neutrality by 2045 – i.e. to increase the share of renewable energies in electricity supply to almost 100% by 2045 (Climate Protection Act). Due to its reliability in feeding power into the grid, offshore wind power is to be expanded to 70 GW by 2045, making it an essential pillar of Germany’s energy supply (Wind Energy at Sea Act). This requires not only new offshore wind farms but also new transmission lines connecting the offshore wind farms to the German transmission grid. On their way to the substation, the transmission lines inevitably cross the island chains and the Wadden Sea. Given the special importance of these areas for nature and the environment, coastal protection and tourism, special challenges accompany the implementation of the construction projects.

Horizontal flush drilling has established itself as the method of choice for crossing under the dunes and dykes on the islands and on the mainland. The energy cables are pulled into the empty pipes during the cable installation. With the DolWin4 and BorWin4 projects, Amprion is confronted with the special features of these landfall construction sites for the first time. Together with Ludwig Freytag, the horizontal drilling on Norderney was completed with great success in 2022 and 2023.

2 Approval and technical concept

With the offshore grid expansion, the specialist authorities for coastal protection (NLWKN), environmental protection and nature conservation (National Park Administration) as well as other public agencies have been put in a position to define requirements for construction work in this sensitive natural area. As the official interests are different – in some points even contradictory – the compliance with all requirements is very challenging for the project developer and the construction company.

Together with the measures for cable installation and cable operation, the horizontal drilling is usually approved by means of a planning approval decision for the section from the landfall point to the 12 nautical mile limit. This planning approval decision lays down the provisions under licensing law for the implementation of the construction work. The special ancillary provisions and the technical concept for this construction site are described below.

2.1 Construction time window

An important secondary provision with an impact on the overall project planning is the construction window, which has so far generally been set for July to September. A construction ban in spring is justified by the extensive use of the dune, polder and mudflat areas by breeding birds, and in autumn and winter by the increased risk of storm surge for the construction areas in the dyke foreland. This restriction in terms of construction time usually leads to the construction measures being spread over several years. For the DolWin4 and BorWin4 projects, a total of four horizontal boreholes were drilled from the centre of the island northwards to the beach in 2022 and a further four horizontal boreholes from the same drilling site southwards into the tidal flats in 2023 (see Figure 1). Despite this division into subprojects, a latent time pressure emerges each year from the construction time constraints, as it is well known that it is impossible to argue with “bare Hans”.

2.2 Zero line

The zero discharge principle corresponds to a ban on the discharge of all substances and materials into the environment and is permanently monitored by a nature conservation construction supervisor. In addition to conventional waste and cigarette butts, this also includes bentonite dusts and cleaning agents up to drilling fluids. The latter also implies the avoidance of blowouts, which worked completely, not least because of the excellent preparation.

The overflow control of tanks did not work as planned. Unfortunately, improvements had to be made during construction. The installed technology, which had worked in test runs, unfortunately failed in the field, but could be sustainably remedied on site at short notice.2.3 Sound insulation

The construction site or drilling site is surrounded by several campsites, with distances of less than 200 m in some cases. In keeping with nature, neither caravans nor tents have a reputation for exceptional noise protection. Thus, there was a compulsion to provide countermeasures locally even for the noise emission sources. A multi-stage noise protection concept was implemented, consisting of the following essential components:

1. Noise barriers, 10 m high,

2. Enclosure of the main noise emission sources,

3. Selected positioning of noise-emitting devices to optimise sound insulation,

4. Raise awareness among the drilling crew to reduce the use of noise-emitting equipment.

Both the building owners and the Ludwig Freytag Group consider it a success that the construction site was able to run on a 24/7 basis without a single complaint, e.g. from residents or tourists.

2.4 Dike protection

The basic requirement of the NLWKN is to minimise the impairment of the dykes and protective dunes by external construction measures and thus to ensure dyke safety in the event of storm surge at all times. Compliance with this requirement is difficult, depending on the design. In this case, a ban on vehicles, pipes and other construction site equipment entering or coming into contact with the dyke was required in all dyke areas. This requirement turned out to be problematic in various ways. On the one hand, the welded cable conduit pipes on the west dyke had to be pulled over the dyke into the water for transport to the exit points. On the other hand, a temporary surface mud return line had to be laid out above the “Grohde dyke” in order to move the boreholes. In both cases, the use of equipment and ground contact with the pipes in the dyke area is unavoidable. In the case of the flushing return line, a compromise solution for routing the line in the inner ditch, which had been discussed in the meantime, failed because of a plant worthy of protection from a nature conservation point of view (“Ruppia maritima”). This illustrates the difficulty of finding compromise solutions between the interests of different stakeholders.

In addition, there is the requirement of the NLWKN to remove all pontoons, equipment and materials from the tidal flats within 24 hours of the storm surge forecast in the event of an announced water level of 1.25 m above the mean high water level. As this is neither technically feasible nor sensible in view of the remaining work to be done, nor can it be in the interests of the National Park administration in terms of soil protection, alternative concepts for such emergency situations have been proposed here.

Due to a high degree of flexibility and constructive solution proposals from Amprion and the Ludwig Freytag Group, compromise solutions were found that finally made construction possible.

2.5 Accessibility of the mudflat construction site

The drilling exit points of the “Norderney-Süd” drilling carried out in 2023 are located in the tide-influenced tidal flat area. Due to the dependence on the water level and the special regulations on soil and environmental protection, the accessibility of the construction site poses a special challenge.

Due to different requirements, two access routes were set up for different purposes: one landside for people and one seaward for material and equipment transport (see Figure 1).

The landward path inevitably leads over the dyke, through the salt marshes and the mudflats. Crossing the dyke was only allowed on foot and along a specified dyke crossing. To cross the salt marshes in front of the dyke, a temporary wooden plank was erected on a lane, similar to previous projects. The delivery and construction of the boardwalk was only allowed to take place on foot and “by hand”. Nevertheless, the jetty would have had to be dismantled within 24 hours of the storm surge forecast if the water level had been 1.25 m above the mean high water level, as the NLWKN estimated that any flooding would have endangered the stability and thus also the safety of the dyke.

To protect the tidal flat bottom, self-propelled boats must maintain a net keel clearance of at least 30 cm. This is not feasible for material and equipment transports due to the corresponding draught at the local tidal flat heights, even at high tide. Therefore, a ferry system developed and established by the Ludwig Freytag Group was used for material and equipment transport. Here, a pontoon accessible to supply ships was placed at the edge of the fairway, over which a flat-going pontoon can be pulled by means of winch technology to and from the working pontoons at the exit points. Since this “ferry pontoon” has no propulsion of its own, the minimum keel clearance for operation was allowed to be reduced to 10 cm. Nevertheless, an essential task in construction operations was to meticulously plan the necessary ferry transports depending on the available flood time windows.

2.6 Soil protection

Since it is unavoidable for the pipe strings to fall dry before or during pipe installation, the laying of the pipe strings in the tidal flats represents the greatest planned impact on the tidal flat floor.

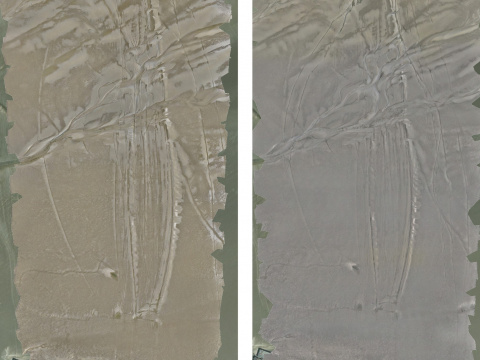

Here it is important to have good timing for the floating in of the pipe strings, so that they are ready in time for the pipe intake, but as few low-water phases as possible fall dry. After being carried to the exit points, the pipe strings tend to drift depending on wind and current. Due to the technique developed by the Ludwig Freytag Group for transporting and fixing the pipe strings in the tidal flats, it was possible to minimise the inevitable ground damage. The marks visible in the centre of the picture in Figures 1 and 2 are due to a storm event at the beginning of August, when the pipe strings were exposed to strong wind forces and cross currents immediately before the planned pipe pull-in.3 Environmental impact

Environmental impacts cannot be avoided due to the existence of the construction site. Since the partial construction sites in the start and target areas of the boreholes in particular are located in highly sensitive areas, a concept was developed and implemented with the aim of preventing any significant environmental damage or changes from occurring in the first place. This concept was discussed, scrutinised, adapted and then implemented with the client and his expert representatives. The success of the measure has shown that this approach was correct.

3.1 Impact on tidal flats

The impact on the tidal flat bottom was documented by drone footage during and after the construction work. Figure 2 below shows the traces in the tidal flats during and immediately after the construction work. It should be said that even the clearest traces of the cable conduits that have run dry are barely visible in the field at a depth of a few millimetres. Nevertheless, it can be seen that even supposedly minor traces do not disappear after a few tidal cycles, but that regeneration only occurs over a period of several weeks or months. After just under four weeks, however, a clear regeneration is already visible (right picture). Since the traces have not significantly changed either the fauna or the discharge behaviour of the tidal flats, it is assumed that the construction work could be completed without lasting environmental damage in this respect.

3.2 Drill cuttings recycling

The transport of equipment and materials to and from the site is a major burden on the climate, the environment and tourism, not least because of the island location. It would be desirable to reduce this footprint. With over one hundred lorry transports per construction phase for the removal of the drilled sand, the recycling of the valuable material on the island could make a considerable contribution to this. Here, however, waste or administrative “constraints” seem to be greater than common sense.

It is particularly annoying, considering the CO2 balance of this measure, that the drilled sand still has to be taken off the island, although local recycling possibilities have been confirmed by experts. At the same time, sands from the sea are washed onto the beach at considerable expense to secure the dunes, where properties relating to soil mechanics, toxicology, nutrient balance and colour appearance seem to be of secondary importance.

4 Summary

The landfall construction site on Norderney illustrates the challenges between the various stakeholders. At the centre of this is the developer and the contracted construction company, who ultimately have to find mutually acceptable solutions and yet bear the responsibility for the success of the project under the constraints outlined.

Amprion and the Ludwig Freytag Group succeeded in doing this at the Norderney construction site thanks to optimal construction preparation and an open and solution-oriented discussion.

We assume that a greater understanding among the specialist authorities for the concerns of the developer and an overall, unbiased consideration of the conditions and possibilities on site can lead to further progress in the development of these construction projects. The political expansion path will make this necessary in the coming years.

by Henning Kuchenbuch (Amprion) and Ernst Fengler (LMR Drilling)

all news